Time:2022-09-19 Reading:5293

Currently, countries worldwide are actively promoting climate neutrality or carbon neutrality, which has driven the rapid development of renewable energy. However, renewable electricity faces the challenge of uneven spatial and temporal distribution. To address this issue, converting renewable electricity into chemical form and transporting it as renewable energy carriers to regions or countries with high energy demand facilitates the redistribution of renewable resources. Therefore, the offshore supply chain of renewable energy carriers is essential for the global industry's comprehensive transition from fossil fuels to renewable energy.

Liquid hydrogen, ammonia, methanol, and liquid methane are considered promising energy carriers that may replace a portion of liquefied natural gas in future maritime scenarios. However, there is limited research on the comprehensive system assessment of the entire supply chain for these four renewable energy carriers. Energy analysis is a crucial method for evaluating and improving the performance of integrated energy systems. It directly reflects the level of technological development and can influence the life cycle emissions and economics of energy systems. However, current energy efficiency assessments for these four renewable energy carriers primarily focus on certain subprocesses in the supply chain, such as electrolysis for hydrogen production and power-to-methane processes, while there is a lack of research on the storage and transportation processes. Additionally, there is limited comparative analysis between the offshore supply chains of different renewable energy carriers.

In response to these, Professor Hanping Chen's team from Huazhong University of Science and Technology published a research article titled "A comparative study on energy efficiency of the maritime supply chains for liquefied hydrogen, ammonia, methanol, and natural gas" in the journal Carbon Capture Science & Technology. Professor Haiping Yang is the corresponding author, and Qianqian Song (a graduate student) is the first author. The study first utilized Aspen Hysys simulation and thermodynamic modeling to conduct energy analysis on various subprocesses in the supply chain system. The study also investigated the impact of vapor recovery on the energy efficiency of the maritime supply chains for the four energy carriers. Furthermore, the study conducted sensitivity analysis on parameters such as environmental temperature, transportation distance, and vessel size. The main contents of the article include:

1.Material and Energy Flow in the Maritime Supply Chain Systems of Four Energy Carriers

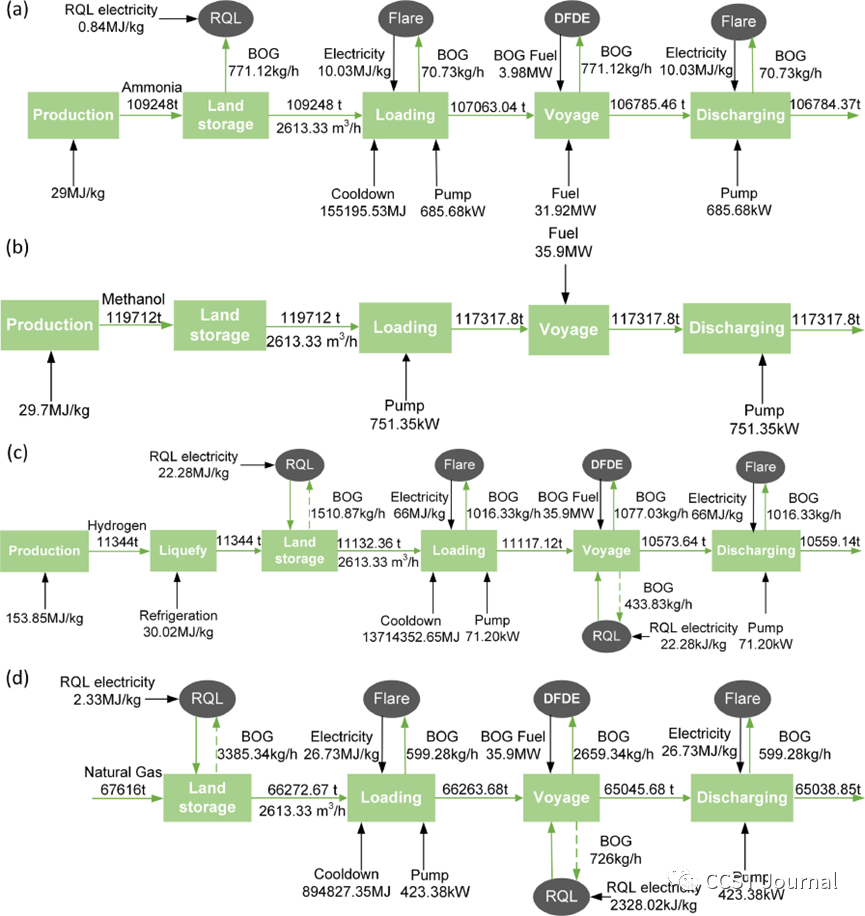

A model of the maritime supply chain systems for the four renewable energy carriers was established, comprising the production stage of liquid energy carriers (including production and liquefaction) and the storage and transportation stage of energy carriers (including port storage, loading, shipping, and unloading). The material and energy flow during the production and transportation processes of renewable energy carriers were further modeled and analyzed.

The results indicate that when produced from renewable energy sources, the energy efficiencies of ammonia, methanol, liquid hydrogen, and liquefied methane supply chains are 97.37%, 98.02%, 89.10%, and 96.23%, respectively. The energy efficiency of the supply chain is influenced by the generation of evaporative gas during cargo handling. The total evaporative gas for ammonia, methanol, liquid hydrogen, and liquefied methane supply chains is 0.0467%, 0%, 2.3660%, and 0.4129%, respectively. The recovery of evaporative gas can increase the energy efficiencies of ammonia, methanol, liquid hydrogen, and liquefied methane by 0.29%, 0%, 4.88%, and 2.10%, respectively, narrowing the energy efficiency gap between liquid hydrogen and the other three energy carriers.

Figure 1. Energy and Mass Flow in the Maritime Supply Chain of Renewable Energy Carriers. (a) Ammonia, (b) Methanol, (c) Liquid Hydrogen, and (d) Liquefied Methane.

2.Impact of Different Parameters on Energy Efficiency in the Storage and Transportation Process

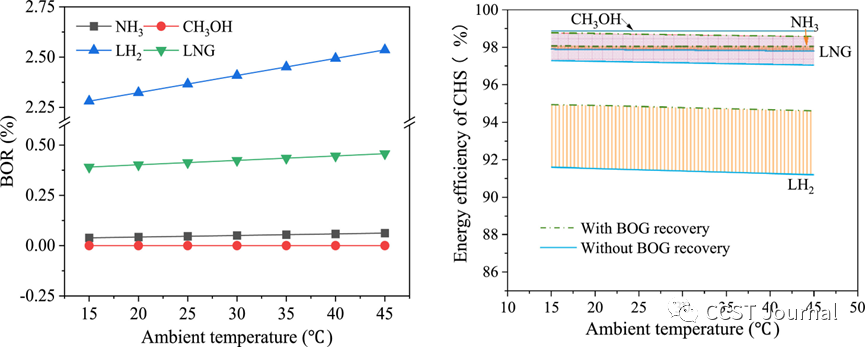

The study conducted sensitivity analysis on energy efficiency, focusing on various parameters such as environmental temperature (15-45 °C), onshore storage time (3-30 days), loading and unloading pipeline length (10-90 days), transportation time (3-30 days), and vessel size (30000-50000 m3). The results revealed that as environmental temperature, storage time at the port, and transportation distance increased, the energy efficiency of the supply chain for renewable energy carriers decreased. On the other hand, an increase in vessel size led to higher energy efficiency. Among the four renewable energy carriers, liquid hydrogen was the most affected by these parameters, followed by liquefied methane, ammonia, and methanol.

However, the impact of these parameters was mitigated when the evaporated gas was recovered, especially for liquid hydrogen and liquefied methane. Ammonia and methanol showed significantly lower energy losses in the maritime supply chain compared to liquid hydrogen and liquefied methane. From an energy efficiency perspective, ammonia and methanol have the potential to replace liquefied natural gas as future energy carriers, while liquid hydrogen would benefit from an efficient evaporated gas recovery system to enhance its competitiveness.

Figure 3. The impact of ship size

The article is from the WeChat official account "Low-Carbon

Technology and Organic Waste Treatment."